- Redo the back brakes following the blatchat method to see if that loosens the rear wheels.

- Change the oil (Fuchs Titan Race Pro S 5w30). 5520 miles on the speedo.

- Put a 3 pin euro plug onto my spare speedo sensor and add to my bag of spares in the car.

- Install the BMS.

Items 1 to 3 caused no headaches but item 4 had me confused for a while with the wiring. I used the lotus 7 club 'how to guide' regarding installing a BMS but some of it just didn't stack up for my car. Therefore for those who wiring is similar to mine I have included some instructions below.

Does your existing wiring match the statements below :

- You have connected a large red cable from the battery +'ve to the right hand pin on the solenoid.

- Connected to the same pin are two brown cables.

- You have an old style ignition switch (metro I think).

- You have no white cables going to your ignition switch.

- You want to install the BMS in the scuttle near to the fusebox.

- You have a BMS which has 2 large connectors and 4 spade type connectors identified as 1 & 2.

If you have this wiring then it matches what I have and the below may be of some use.

Step 1

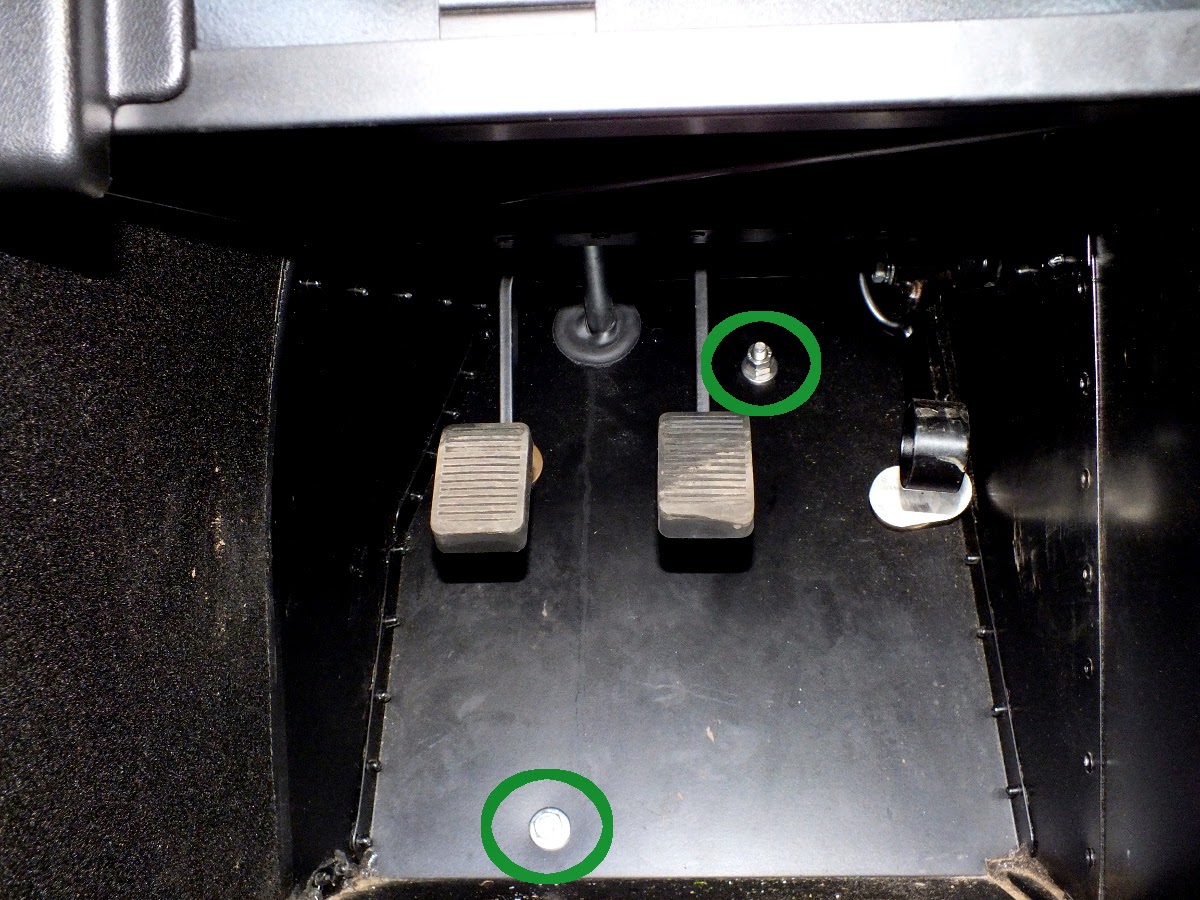

Drill a 20mm hole in the vertical black panel between the engine bay and passenger area. Open up the hole slighty with a dremmel. Apply some chalk to the fixing hole face and push the BMS up against the vertical black panel to identify where the fixing holes need drilling. Fix the BMS using the 2 hex set screws, washers and nylock nuts.

Hole drilled in vertical panel above the passengers knees and next to the fuse box. The fixing holes have been covered in chalk and pushed up against the panel to make where to drill.

Step 2

Disconnect the large red cable from the battery and connect it to the bottom connection of the BMS. In addition to connecting the large red cable to the bottom connection of the BMS, also make up a 3 inch green cable (round lug on one side and spade type connector on the other) and connect it to the bottom connection of the BMS and one of the pins labelled No. 1.

Step 3

Make another 3 inch long green cable (a spade type connector on one end and a through connector on the other), connect the spade to the other No. 1 pin on the BMS and the through connector to one side of the large white resister. Use some heatshrink sleeving to keep everything isolated and looking tidy. Make a 12 inch long green cable (a through connector on one end and a lug on the other). Connect the through connector to the other side of the large white resistor. Connect the lug to an earthing point on the car. There is a spare threaded link in the chassis by the ECU on my car.

Step 4

Mount the white resistor inside the metal bracket which comes with the CC kit. Then use one of the fixings of the BMS to fix the bracket close to the BMS. You may need to open up the bracket with pliers and fold it around the white resistor.

Step 4

Mount the white resistor inside the metal bracket which comes with the CC kit. Then use one of the fixings of the BMS to fix the bracket close to the BMS. You may need to open up the bracket with pliers and fold it around the white resistor.

N.B. There are four pins, 2 labelled No. 1 and 2 labelled No. 2. The number 1 pins are normally closed when the BMS key is off or has been removed This means that the resister connected will take any energy from the solenoid to earth when you switch the BMS off and remove the key.

Step 5

Take the back off the ignition and identify the pin which has two cables into one spade connector. The original instructions says these are white cables but I found they were black on my wiring loom. They were also connected to connector number 30 on the ignition. See below.

The cables I needed to disconnect from the back of the ignition were the two black ones on the lower right, connection number 30. Keep the black cables together in the white plastic connector.

Step 6

Make two lengths of cable which can reach from the ignition to the BMS pins labelled no. 2. The first cable is connected to the two cables which are in the white plastic connector and to one of the pins labelled no. 2 on the BMS. The second cable connects to the ignition where the two black cables used to be (connection number 30), the other end connects to the other pin labelled no. 2 on the BMS.

N.B. There are four pins on the BMS, 2 labelled No. 1 and 2 labelled No. 2. The number 2 pins are normally closed when the BMS key is in and switched on. This means that the power gets to the ignition switch when the BMS is on.

I imagine the above is a little confusing due to the connection names I have adopted and so hopefully the photograph below helps.

Cable A : Large Red Cable : From top BMS connector to battery +'ve.

Cable B : Large Red Cable : From Solenoid to bottom BMS connector.

Cable C : Small Green Cable : From bottom BMS connector to No. 1 pin on BMS.

Cable D : Small Green Cable : From No. 1 pin on BMS to one side of white resistor.

Cable E : Small Green Cable : From other side of white resistor to car earthing point.

Cable F : Small Black Cable : From two black cables disconected from the ignition to one of the No. 2 pins on BMS.

Cable G : Small White Cable : From other No. 2 pin on BMS to ignition connection No. 30.

The finished switch installed with the key in the off position.